Discover the complete steel frame solution;

FastWall PRODUCT

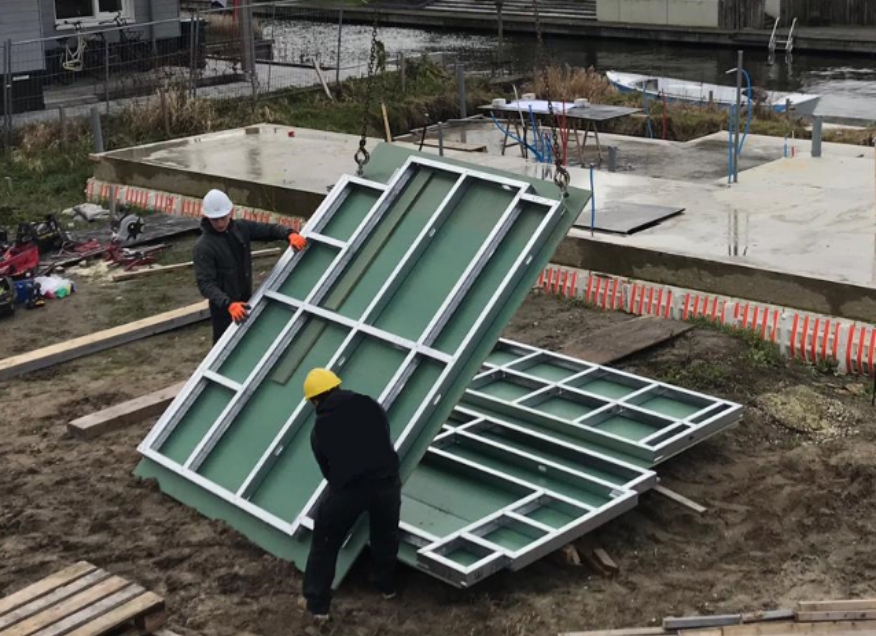

Ready-to-install steel panels.

Prefabricated, custom-made, and finished with a structural sheating, our 2D panels offer a turnkey solution to build faster and more efficiently.

Accurate, durable, and high-performing, they speed up your construction projects while ensuring top-quality results and reducing waste.

-

1

Shortened construction timelines

-

2

A clear and quick overview of your project

-

3

A superior construction quality with unmatched precision

FASTWALL PRODUCT

FastWall product: faster, more precise, and more sustainable construction!

FastWall is designed to meet the demands of modern construction. This innovative product consists of fully assembled, ready-to-use steel panels with a high-quality structural coating. Designed, pre-cut and factory-assembled, they guarantee a high-performance, efficient solution for any type of project.

At beSteel, we master every stage: design, engineering and production of cold-formed steel profiles. This expertise ensures that FastWall is as reliable as possible, making it a key asset for your architectural projects.

With FastWall, contractors and construction companies save valuable time while benefiting from exceptional quality. With our turnkey solution, speed, durability, and flexibility come together to transform your architectural projects.

-

1

Custom Design: Our team of engineers digitally designs your project. Together, we validate every detail to create the perfect steel structure for your house, extension, apartment, or loft conversion.

-

2

Off-site Manufacturing: The steel profiles are assembled into 2D panels in our beSteel workshop, using high-precision automated production equipment for optimal results.

-

3

Structural Coating Included: We integrate a high-quality structural coating to further accelerate the construction process.

-

4

Approach Durable et Circulaire: We follow the cradle-to-cradle concept, using only what is necessary, reusing waste, and producing in a circular manner.

-

5

Optimized Transport: Once the 2D panels are manufactured, we facilitate their transportation from our workshop to the construction site.

-

6

Quick On-Site Assembly : On-site, the conversion into a steel framework is quick and simple. We provide a complete A to Z manual, and our team remains available to support you throughout the process.

Discover a project completed

with our FastWall product

Also discover